Order by 2PM MST!

How to Accurately Measure Flanges and Gaskets: A Guide by United Built Water Trucks

How to Accurately Measure Flanges and Gaskets: A Guide by United Built Water Trucks

Accurate measurement of flanges and gaskets is crucial in ensuring proper fit and function in various applications, particularly in the water transportation and infrastructure industry. At United Water Trucks, we understand the importance of precision in these measurements, and we've created this comprehensive guide to help you measure flanges and gaskets correctly. Whether you're a seasoned professional or new to the field, this guide will provide you with the essential knowledge to get the job done right.

Understanding the Basics: Flanges and Gaskets

Before diving into the measurement process, it’s important to understand what flanges and gaskets are and their roles in piping systems.

Flanges are flat, round components used to connect pipes, valves, pumps, and other equipment to form a piping system. They provide a means of assembling and disassembling the system for maintenance or repair.

Gaskets are mechanical seals that fill the space between two mating surfaces, typically flanges, to prevent leakage of fluids. They are made from various materials depending on the application and the nature of the fluids being transported.

Key Measurement Principles

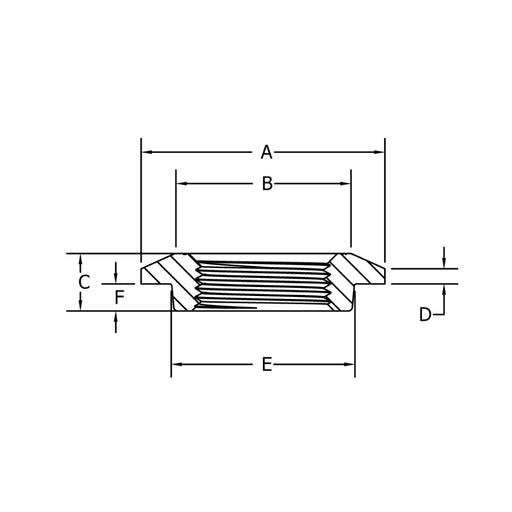

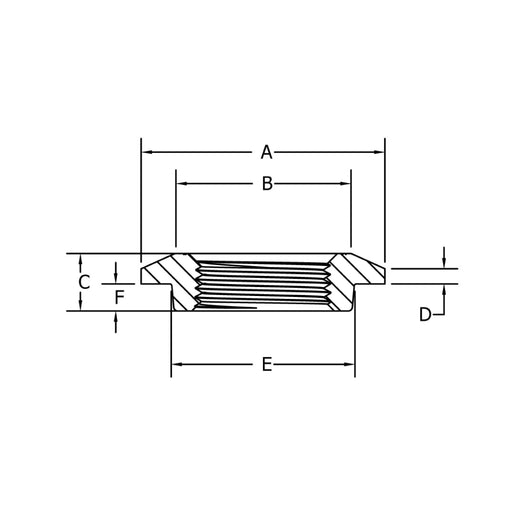

When measuring flanges and gaskets, certain principles apply to ensure accuracy and consistency. These principles include understanding the bolt circle, outside diameter, inside diameter, and sealing surface.

1. Bolt Circle Diameter (BCD)

The bolt circle diameter (BCD) is the measurement of an imaginary circle passing through the centers of all the bolts in a round pattern on a flange. This is a crucial measurement for ensuring that the flange and gasket will align properly during assembly.

- How to Measure: Measure from the center of one bolt directly across to the center of the opposite bolt. This will give you the diameter of the bolt circle.

- Visual Aid: Imagine a blue dashed circle passing through the centers of the bolts as depicted in the drawing above.

2. Outside Diameter (OD)

The outside diameter (OD) is the measurement of the outer edge of the flange or gasket. This measurement is important for ensuring that the flange and gasket will fit within the designated space and will not interfere with other components.

- How to Measure: Measure from one outer edge directly across to the opposite outer edge of the flange or gasket.

3. Inside Diameter (ID)

The inside diameter (ID) is the measurement of the inner edge or the hole of the flange or gasket. This is critical for ensuring that the flange and gasket will fit around the pipe or fitting they are meant to connect.

- How to Measure: Measure from one inner edge directly across to the opposite inner edge of the flange or gasket.

4. Sealing Surface

The sealing surface is the area of contact where the gasket is placed to seal between two flange connections. Proper measurement of the sealing surface ensures that the gasket will effectively prevent leaks.

- How to Measure: Ensure the measurement covers the entire contact area where the gasket will be placed between the two flanges.

Measurement Best Practices

To ensure accuracy, all measurements should be made across the center of the flange or gasket. Here are some additional tips to keep in mind:

- Use Calipers: For the most precise measurements, use a pair of calipers. This tool allows you to measure the diameter accurately.

- Double-Check Measurements: Always double-check your measurements to avoid errors that could lead to improper fitting and potential leaks.

- Consult Specifications: Refer to the manufacturer’s specifications for standard flange and gasket sizes to ensure compatibility.

- Record Measurements: Keep a detailed record of your measurements for future reference and to ensure consistency in your work.

Conclusion

Accurate measurement of flanges and gaskets is essential for the proper functioning of piping systems. By understanding and applying these measurement principles, you can ensure that your components will fit correctly, providing a secure and leak-free connection. At United Water Trucks, we are committed to providing you with the knowledge and tools you need for success in your projects.

- Flange measurement

- Gasket measurement

- Bolt circle diameter

- Outside diameter

- Inside diameter

- Sealing surface

- Accurate measurements

- Piping systems

- United Water Trucks

- Mechanical seals

- Leak prevention

- Water transportation

- Infrastructure maintenance

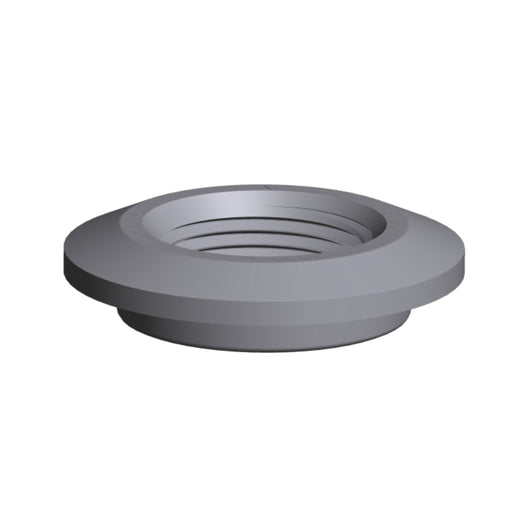

Featured Tank Flanges

-

53 in stock

Tank Flange 1/2", Series 300, Phoenix Forge (THRFLGP0050)

Phoenix ForgeOriginal price $0.00 - Original price $0.00Original price $0.00$9.67$9.67 - $9.67Current price $9.67Tank Flange, Boiler Flange with Pilot, 1/2" A 1.625 B 1.188 C .468 D .140 E 1.125 F .188

Original price $0.00 - Original price $0.00Original price $0.00$9.67$9.67 - $9.67Current price $9.67 -

3 in stock

Tank Flange 1/4", Series 300, Phoenix Forge (THRFLGP0025)

Phoenix ForgeOriginal price $0.00 - Original price $0.00Original price $0.00$5.74$5.74 - $5.74Current price $5.74Tank Flange, Boiler Flange with Pilot, 1/4" A 1.312 B .812 C .406 D .094 E .875 F .125

Original price $0.00 - Original price $0.00Original price $0.00$5.74$5.74 - $5.74Current price $5.74