Order by 2PM MST!

Cam & Groove Fittings for Water Trucks: Lightweight, Secure, and Corrosion-Resistant

Cam & Groove Fittings for Water Trucks: Lightweight, Secure, and Corrosion-Resistant

When it comes to maintaining a reliable water truck system, having the right fittings is essential. At United Built Water Trucks, we understand how crucial every connection is—and that’s why we offer premium Cam & Groove fittings that are built for performance. In this blog, we’ll explore the key benefits of aluminum camlock fittings, how they work, and why they’re a top choice for water truck operators across industries.

What Are Cam & Groove Fittings?

Cam & Groove fittings, often referred to as camlock fittings, are a quick-connect system designed to securely join hoses and pipes. These fittings consist of two primary parts:

-

Grooved Male Nipple (Adapter): The insertable end that provides a tight seal when connected.

-

Female Cam (Coupler): Equipped with cam arms that lock the adapter in place with a simple, secure motion.

When the adapter and coupler are joined, the result is a leak-resistant, reliable connection that holds up under pressure—ideal for heavy-duty applications like water trucks, dust control, and irrigation systems.

Why Aluminum Camlock Fittings Are the Preferred Choice

Among the many materials used for cam & groove fittings, aluminum stands out for several important reasons:

-

Lightweight and Durable: Aluminum camlock fittings are significantly lighter than stainless steel, making installation and maintenance easier without compromising strength.

-

Corrosion-Resistant: Aluminum naturally resists rust and corrosion, especially when used in outdoor or wet environments—making them perfect for water truck parts.

-

Cost-Effective: Aluminum fittings offer a solid balance of performance and price, providing a reliable solution without breaking the bank.

Applications for Water Truck Operators

Whether you're outfitting a new tank or upgrading an existing spray system, Cam & Groove fittings play a vital role in your water truck's functionality. Common use cases include:

-

Connecting hoses to pumps for rapid water transfer

-

Integrating with spray bars or valve systems for dust suppression

-

Attaching fill lines for quick water intake

With their quick-connect design, aluminum camlocks minimize downtime and simplify routine maintenance—a major plus for job site efficiency.

Why Choose United Built for Your Fittings

Our fittings aren’t just standard parts—they’re carefully selected and tested to meet the demands of real-world fieldwork. United Built offers:

-

A wide range of male and female camlock fittings in multiple sizes

-

Compatibility with other key components like inline control valves, spray systems, and water pumps

-

Expert support to help you choose the right fitting for your application

Conclusion: Seal the Deal with the Right Camlock Fittings

If you're searching for lightweight, durable, and corrosion-resistant Cam & Groove fittings for your water truck, United Built Water Trucks has what you need. Our high-quality aluminum camlock fittings are engineered for performance and trusted by professionals across construction, agriculture, and municipal services.

Browse our full selection of water truck parts today and experience the reliability and ease of premium quick-connect fittings.

Cam & Groove Fittings

Camlock Gasket, Buna

UnitedBuilt ChoiceCamlock Gasket, Buna

Camlock, Type A, Male Cam x Female NPT, Aluminum

UnitedBuilt ChoiceCamlock, Type A, Male Cam x FNPT, Aluminum

Camlock, Type B, Female Cam x Male NPT, Aluminum

UnitedBuilt ChoiceCamlock, Type B, Female Cam x Male NPT, Aluminum

Camlock, Type F, Male Camlock x Male NPT, Aluminum

UnitedBuilt ChoiceCamlock, Type F, Male Camlock x Male NPT, Aluminum

Camlock, Type E, Male Camlock x Hose Barb, Aluminum

UnitedBuilt ChoiceCamlock, Type E, Male Camlock x Hose Barb, Aluminum

Camlock, Type D, Female Cam x Female NPT, Aluminum

UnitedBuilt ChoiceCamlock, Type D, Female Cam x Female NPT, Aluminum

Camlock, Type C, Female Cam x Hose Barb, Aluminum

UnitedBuilt ChoiceCamlock, Type C, Female Cam x Hose Barb, Aluminum

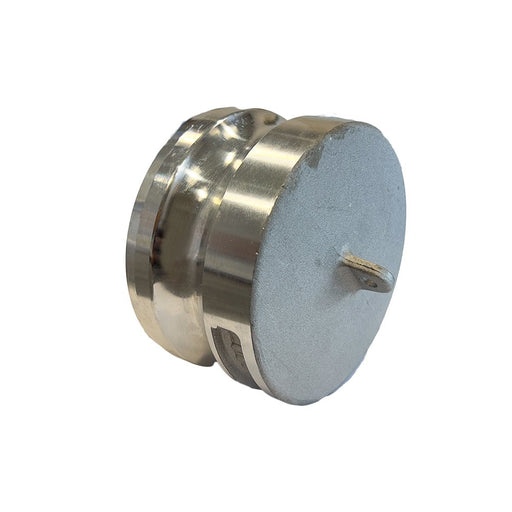

Camlock, Type DC, Dust Cap, Aluminum

UnitedBuilt ChoiceCamlock, Type DC, Dust Cap, Aluminum

Camlock, Type DP, Dust Plug, Aluminum

UnitedBuilt ChoiceCamlock, Type DP, Dust Plug, Aluminum

Featured Cam & Groove Fittings

-

30 in stock

Camlock Gasket, Buna

UnitedBuilt ChoiceOriginal price $0.00 - Original price $0.00Original price $0.00$0.96 - $1.86$0.96 - $1.86Current price $0.96Camlock Gasket, Buna

Original price $0.00 - Original price $0.00Original price $0.00$0.96 - $1.86$0.96 - $1.86Current price $0.96 -

1 in stock

Camlock, Type A, Male Cam x Female NPT, Aluminum

UnitedBuilt ChoiceOriginal price $0.00 - Original price $0.00Original price $0.00$5.94 - $60.00$5.94 - $60.00Current price $5.94Camlock, Type A, Male Cam x FNPT, Aluminum

Original price $0.00 - Original price $0.00Original price $0.00$5.94 - $60.00$5.94 - $60.00Current price $5.94 -

8 in stock

Camlock, Type B, Female Cam x Male NPT, Aluminum

UnitedBuilt ChoiceOriginal price $0.00 - Original price $0.00Original price $0.00$12.40 - $30.80$12.40 - $30.80Current price $12.40Camlock, Type B, Female Cam x Male NPT, Aluminum

Original price $0.00 - Original price $0.00Original price $0.00$12.40 - $30.80$12.40 - $30.80Current price $12.40 -

11 in stock

Camlock, Type F, Male Camlock x Male NPT, Aluminum

UnitedBuilt ChoiceOriginal price $0.00 - Original price $0.00Original price $0.00$8.64 - $55.00$8.64 - $55.00Current price $8.64Camlock, Type F, Male Camlock x Male NPT, Aluminum

Original price $0.00 - Original price $0.00Original price $0.00$8.64 - $55.00$8.64 - $55.00Current price $8.64 -

2 in stock

Camlock, Type E, Male Camlock x Hose Barb, Aluminum

UnitedBuilt ChoiceOriginal price $0.00 - Original price $0.00Original price $0.00$7.36 - $20.46$7.36 - $20.46Current price $7.36Camlock, Type E, Male Camlock x Hose Barb, Aluminum

Original price $0.00 - Original price $0.00Original price $0.00$7.36 - $20.46$7.36 - $20.46Current price $7.36 -

14 in stock

Camlock, Type D, Female Cam x Female NPT, Aluminum

UnitedBuilt ChoiceOriginal price $0.00 - Original price $0.00Original price $0.00$15.12 - $34.38$15.12 - $34.38Current price $15.12Camlock, Type D, Female Cam x Female NPT, Aluminum

Original price $0.00 - Original price $0.00Original price $0.00$15.12 - $34.38$15.12 - $34.38Current price $15.12 -

5 in stock

Camlock, Type C, Female Cam x Hose Barb, Aluminum

UnitedBuilt ChoiceOriginal price $0.00 - Original price $0.00Original price $0.00$14.88 - $36.66$14.88 - $36.66Current price $14.88Camlock, Type C, Female Cam x Hose Barb, Aluminum

Original price $0.00 - Original price $0.00Original price $0.00$14.88 - $36.66$14.88 - $36.66Current price $14.88 -

4 in stock

Camlock, Type DC, Dust Cap, Aluminum

UnitedBuilt ChoiceOriginal price $0.00 - Original price $0.00Original price $0.00$10.46 - $27.05$10.46 - $27.05Current price $10.46Camlock, Type DC, Dust Cap, Aluminum

Original price $0.00 - Original price $0.00Original price $0.00$10.46 - $27.05$10.46 - $27.05Current price $10.46 -

3 in stock

Camlock, Type DP, Dust Plug, Aluminum

UnitedBuilt ChoiceOriginal price $0.00 - Original price $0.00Original price $0.00$6.05 - $15.12$6.05 - $15.12Current price $6.05Camlock, Type DP, Dust Plug, Aluminum

Original price $0.00 - Original price $0.00Original price $0.00$6.05 - $15.12$6.05 - $15.12Current price $6.05